The filling operation can be propelled by high accuracy rotary piston pumps or peristaltic pumps, depending upon the nature of product and client’s requirement. Servo driven pick and place type plungering operation is done by pipe in – pipe out (tube vent) basis in case of aqueous liquid and vacuum assisted plungering is done when the liquid is viscous.

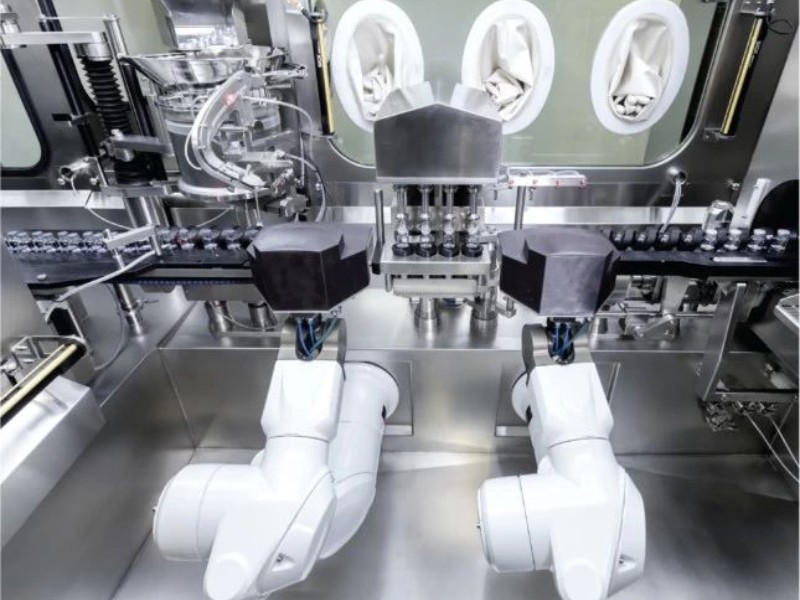

The machine we offer has Open RABS (Restricted Access Barrier System), we can also provide it in Closed RABS and Isolator along with 21 CFR part 11 compliance SCADA system.