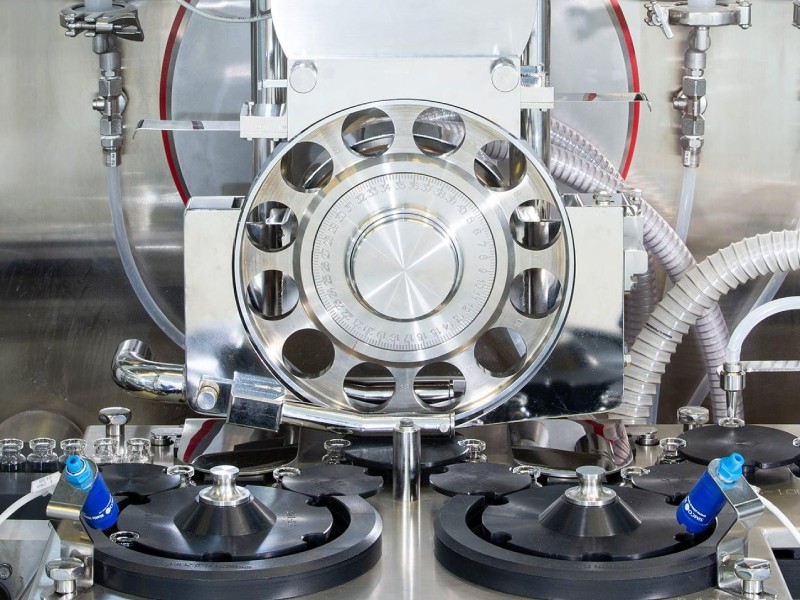

Automatic High Speed Injectable Dry Powder Filling with Rubber Stoppering Machine is completely mechanical driven machine with self picking roller based rubber stoppering system. This machine has a very sturdy design and can withstand long working hours. Filling is done with help of vacuum and air pressure based powder wheel with manual fill weight setting.

| Model | DPPF-120 | DPPF-240D |

|---|---|---|

| Filling Speed | 120 Vials/minute Based On 5-10ml Vial For Single Dosage (Depending Up On Size/types Of Vial & Powder Density) | 240 Vials/minute Based On 5-10ml Vial For Single Dosage (Depending Up On Size/types Of Vial & Powder Density) |

| Design | Left To Right | |

| Dosage | 50 Mg To 1.5 Grams. Single Dose (with Change Parts) 1.5 Grams To 6 Grams. Double, Triple And Four Doses. Fill Range Depending Upon Vial Opening And Bulk Density Of Powder. Under Controlled Level Of Humidity (i.e. 25%) | |

| Dosing Wheel | One | Two |

| Dosing Port / Wheel | 8 Nos | |

| Fill Accuracy | ±2% Depending Upon Consistency And Uniformity Of Bulk Density Of Injectable Powder | |

| Product Conveyor | 50 Mm (2″) Wide Delrin Conveyor | |

| Powder Suction | Through Vacuum | |

| Powder Delivered | Through Air/Nitrogen (Customer To Provide) | |

| Stopper Delivered | Through Vibratory Bowl & Chute | |

| Machine Dimension | 1830 (mm) X 915 (mm) X 1600 (mm) | 2100 (L) X 1170 (W) X 1600 (H) |